Dawson Sheet Pile Capping System

Bottom Shuttering

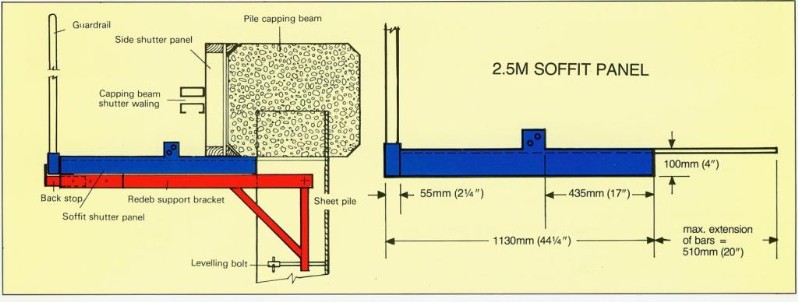

The Dawson capping system is a Formwork System forming bottom shuttering for casting capping beams on sheet pile walls.

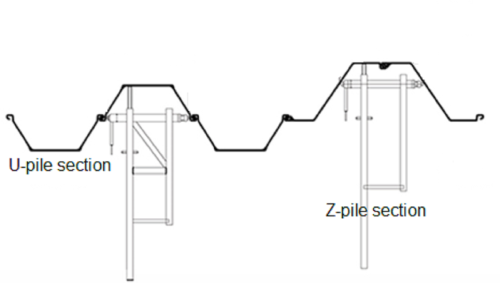

The system is usable for both U- and Z-piles

The system can be reused one time after another

– and it is usable for both U- and Z-piles.

Please see also:

Capping System Components

The System consists of:

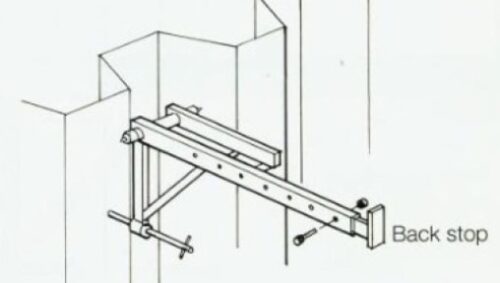

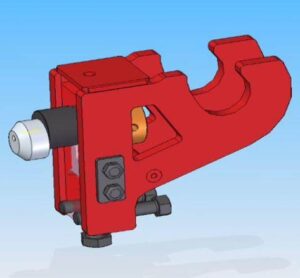

- Steel Support Brackets to be fastened between the sheet piles with bolts with hard points in the center of the bolt heads. By fastening, the points bore into he sheets. Alternatively the brackets are fastened to special fittings, MDBS (Medium Duty Support Brackets) – see picture below. The MDBS are used for mounting on the flat side of sheet piles and Combi Walls, and locked to the piles with their integrated eccentrics in purpose-drilled holes.

- Soffit Shutter Panels (mats) with rectangular bars retained within a framework are placed in continuation of each other. The bars are free to slide within the set limits. With the panel secured on the brackets the bars are pushed towards the wall of piles.

Principle Sketch

Principle Sketch - Support Brackets mounted

Sketch - Support Bracket with backstop

Panel with Handrail

Support Bracket mounted between Sheet Piles

MDBS - Medium Duty Support Bracket

Support Bracket in MDBS

MDBS Fastened with the Integrated Excentric

Installation of the Sheet Pile Capping System

Support Brackets are attached to each “belly” of the sheet pile wall with their bolts. The hard points of the bolts drill into the surface of the sheet and hold the bracket when the bolts are tightened. On U-sheets the bolts are screwed onto the locks – on Z-piles on the flat part.

For mounting Support Brackets on pipes or the flat part of sheet piles, a MDBS (Medium Duty Support Bracket) is attached in a purpose-drilled hole.

After fixing, the Support Brackets are adjusted with the lower leveling screws to level the upper rods.

The panels are placed on the brackets and bolted together, and the rectangular bars pushed towards the pile wall starting with the deepest part of each sheet pile. Finally backstops are mounted.

The rods are preferably treated with mold oil to prevent adhesion of concrete.

Advantages of the Sheet Pile Capping System

- The equipment can be used one time after another and is applicable to all types sheet piles.

- Equipment with Support Brackets and Soffit Panels is quickly assembled by unskilled personnel after a short introduction.

- The formwork system eliminates the need for individual wooden panels adapted to the profiles and welding with subsequent removal of welded-on fittings.

- The standard Soffit Panels can be used for many types of caps.

Productivity

- Fifty Support Brackets with Panels and shuttering are mounted in a day. This corresponds to 50 running m cap.

- The equipment is advantageously divided in two or more sets so that they each cover a section of pre-selected number of running m. One section can thereby be cast while another is assembled and a third dries.

- Six hours after casting the Panels and Support Brackets are ready for disassembly and ready for further use.

Capping System Monted

One Section Cap Casted