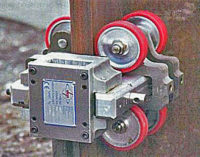

Dawson Sheet Pile Threader – an indispensable tool for sheet pile interlocking

Use a Sheet Pile Threader for safe and rapid sheet pile interlocking

Replaces the “Top man” or “Pile Monkey” who otherwise carries out the interlocking by hand.

Greatly reduces the risk by interlocking piles in severe weather conditions.

Saves time, money and lives.

The Universal Sheet Pile Threader can be used for most sheet piles.